Harvest is in full swing!

Harvest 2025 By the Numbers

Warmer weather pushed many of our vineyards to optimal ripeness following a steady and temperate summer, making for a consistent and paced-out harvest. After receiving some light overnight rain at the end of September, there has been a pause in bringing in fruit. We’ve brought in approximately half of our fruit and are waiting for the perfect moment to harvest the remaining clusters. Kirk Venge, winemaker, is anticipating a stellar year with fruit exhibiting bright acidity, balanced characteristics, and good aging potential.

Of course, picking and processing the grapes at the winery is just the first step of harvest. The grapes that have already been brought to the winery are being made into wine. Mother Nature did its job; now it is our turn to do ours.

On the Crushpad

On the Crushpad

If you’ve ever visited B Cellars during harvest, you’ve probably seen one of the most dynamic parts of the winemaking process: the punchdown.

As fermentation begins, yeast cells convert the natural sugars in the grape juice into alcohol (cheers to that!) and carbon dioxide. The CO₂ causes the grape solids — the skins and seeds — to rise to the top of the tank, forming what’s known as the cap. Beneath it, the fermenting juice keeps bubbling with activity.

Breaking through the cap is essential to the wine-making process. To do this, our production team performs punchdowns by hand using a long steel tool that resembles an oversized potato masher. This tool helps us gently push the cap back down into the juice.

Why do we do it? A few key reasons:

Extraction: Good contact between the juice and the grape skins draws out color, flavor, and tannin structure.

Temperature Control: Breaking up the cap helps release built-up heat from fermentation.

Oxygenation: A small dose of oxygen keeps yeast cells healthy and fermentation on track.

It’s a straightforward but essential step — and yes, it’s also a serious workout for our cellar crew! Each punchdown brings us closer to turning beautiful grapes into expressive, handcrafted wines.

In the Winery

In the Winery

We use multiple fermentation vessels: oak barrels, t-bins, concrete, and stainless steel tanks. However, regardless of where the wine ferments, it always returns to a stainless steel tank for racking before being transferred to oak barrels for aging. This transition marks a shift from the lively, bubbling activity of fermentation to a slower, more refined stage where flavors deepen and the wine begins to reveal its true character.

The process starts with racking, which simply means transferring the wine from the tank, leaving behind the heavier solids like grape skins, seeds, and spent yeast that settle at the bottom. We use hoses and gentle pumps to move the wine carefully, minimizing oxygen exposure to keep its fresh, bright flavors. Next, the wine flows into oak barrels to rest for 6-18 months, depending on the varietal.

After removing the wine from the tank, the solids remain at the bottom, and the next labor-intensive step begins: emptying the tank. Our team uses shovels and rakes to remove all grape skins and seeds, which are then composted and used as fertilizer for our vineyards. Our first tank to be emptied was Beckstoffer Bourn Vineyard Petite Sirah—we can’t wait to see it start aging in our cave.

SHOP THE HARVEST

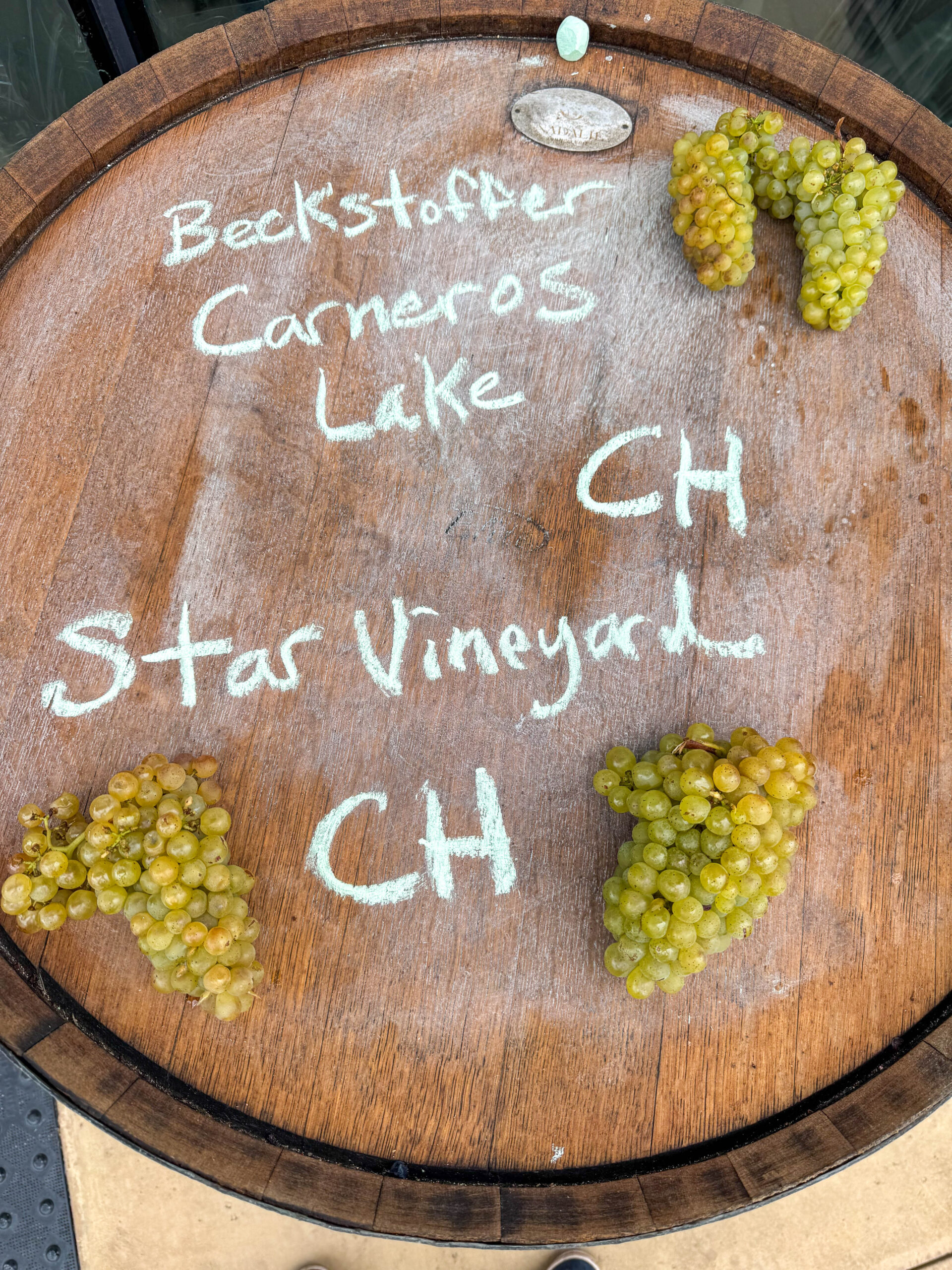

2022 Star Vineyard Chardonnay

2023 Beckstoffer Carneros Lake Vineyard Chardonnay

2022 Brown Ranch Pinot Noir

Leave A Comment