The sun is shining again in the Napa Valley. It feels so good simply to breathe in clean air. While we are finished with the harvest, and all of our grapes for the vintage are in, we are hardly finished with what we call the “harvest season” or the “crush.” Managing fermentations, pressing wines, cleaning tanks, barreling down…we’ll be on the job for a few more weeks to see everything through. If you have a hankering to get out and see us, the next few weeks present a perfect window of opportunity, and there is still a lot to see, taste, and smell around the winery.

The pace of this later part of crush feels more like a good band in the middle of a jam, as compared to the controlled chaos of the first part of harvest. The team know each other well. There is an easy rhythm to the pumpovers and punch downs, the set up and the clean up. It’s a cool vibe, and we’d love for you to check it out with a late-season Harvest Trek. You’ll find Napa full of hotels, restaurants, and wineries working hard to welcome you.

We’re done picking. Let’s make some wine!

Extraction

Getting the good out of the grapes and into the wine

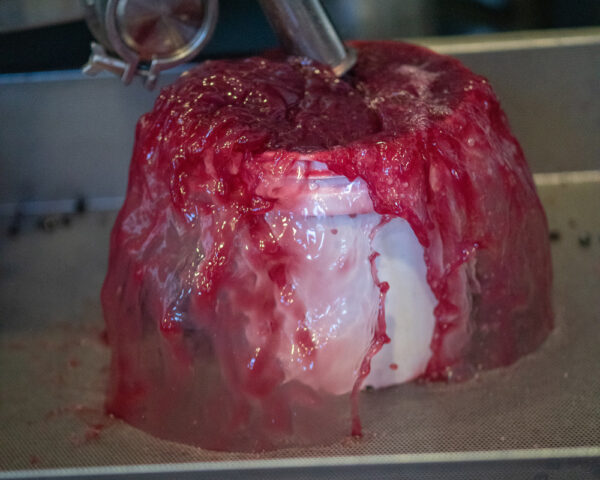

The Cap

When the grapes come through the destemmer and the optical sorter and then are loaded into a fermentation tank, they are broken open and begin to bleed their juices. The weight of the grapes in the fermenter further squeezes their juices out. The emptied out skins begin to float to the surface, creating the “cap” which is a thick floating carpet of skins on the top of the fermenting juice. Depending on the size and the shape of the tank, the cap can be anywhere from several inches to several feet thick.

The problem with this is that there is still a lot of goodness in these skins which make up the cap. So we want to get the cap back into contact with the fermenting juice so that the water and the alcohol in the juice can work to dissolve or leach the compounds and molecules which color wine, the tannins which provide structure and flavor, and the innumerable compounds which provide the smorgasbord of aromas in a wine.

We also do this to break open the cap so that the fermenting wine can get a big breath of oxygen. This will help to keep the yeast happy, healthy, and feasting on sugar.

To do that we employ two main tactics at B Cellars.

Punch Down

Punching down by hand is simple. The cellar worker takes a steel tool which looks a little like a giant potato masher and pushes the cap into the juice. This is typically done up to 3 times per day. In addition to making the wine taste great, punching down by hand is a great workout!

Pump Over

In larger tanks, we employ a pumpover. We pump fermenting juice from the bottom of the tank and spray it from a hose over the cap. Often, we let the juice spill from the tank valve into a tub and pump from the tub to increase oxygen in the juice. The juice spills down through the cap, leaching out the good stuff from the skins in the cap.

Leave A Comment